FROM THERMOPLASTIC MOULDING

TO STAINLESS STEEL WORK:

WE BRING

YOUR IDEAS

TO LIFE

We are able to design and manufacture highly complex

moulds with top level technical solutions. Our highly automated moulding workshop ensures the

reliability of processes, component quality and complete

traceability of materials which is an indispensable condition

for all products in contact with foodstuffs.

Our metalworking departments can produce high-precision

items with strict requirements as to both design and function. Over the years, Tecniplast OEM has developed special expertise in

processing stainless steel.

The internal design resources are able to develop moulds of great complexity both for technical components with close dimensional tolerances and for components with high aesthetic requirements.

Our tooling shop floor, equipped with cutting-edge technologies, and the network of Italian and international partners allow us to manufacture mould of excellent quality and reliability in a very short time.

Our experience in mould testing and fine-tuning allows us to minimize downtime and quickly proceed to actual production, strictly respecting all technical and functional specifications.

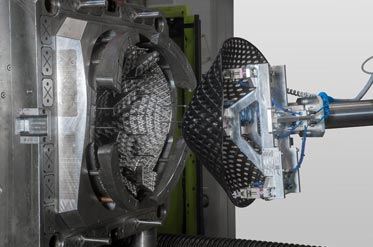

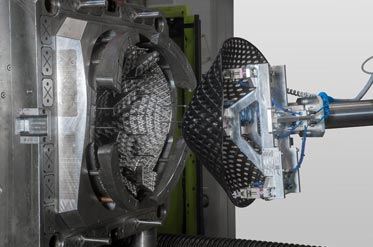

Our moulding department employs injection moulding machines from 10 to 2000 tons, equipped with anthropomorphic robots that allow the handling of the moulded parts and the possible automatic loading of inserts.

Our robots also perform complementary operations such as cutting sprues through laser cutting systems, drilling, milling and assembling directly in the moulding cell, using cutting-edge technologies such as robotic structural gluing, laser welding and ultrasounds.

The strict process control allows great stability of the moulding parameters to obtain high aesthetic characteristics and top dimensional precision.

Our expertise covers the fabrication of sheets, pipes and wire structures made of stainless steel using laser cutting systems, numerically controlled bending centers with automatic tool changers, TIG and MIG welding stations, deburring and sandblasting systems.

Our long experience in the construction of products demanding high reliability and that operate in severe environmental conditions allows us to produce high quality components with excellent aesthetic finish, optimizing the consumption of materials through careful preparation of cutting nesting.

Our deep-rooted quality culture enables us to develop from the beginning of each project all the necessary actions to ensure complete compliance with specifications and to minimize the variability of processes; the measuring machines and the instrumentation of the metrological laboratory allow us from the first mold test to verify the geometry of each piece, to calculate the process capacity and to define the control plans to be applied in production.

The rigorous control of the production allows us to guarantee reliability and repeatability over time; the traceability of the lots of materials and components allows us to intercept in the bud and correct any drift.